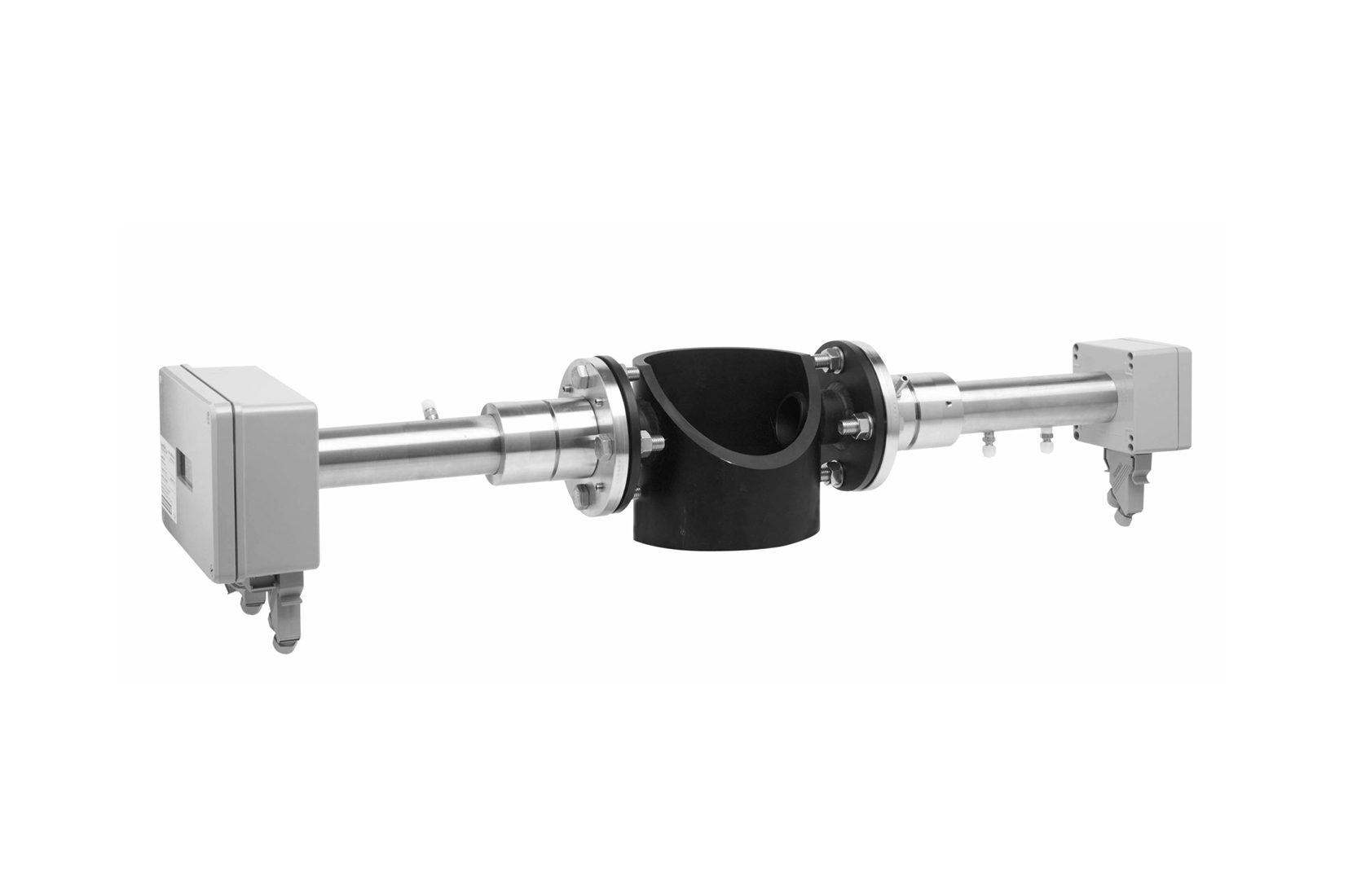

LaserGas™ II SP

Features

check

Fast response time

check

Wide variety of gases and applications

check

Well proven and robust design

Description

LaserGas™ II Single Path is a non-contact optical measurement method also known as in-situ. The analyzer is suitable for variety of gases and process conditions, including dual gas measurements.

Laser Gas™ II SP has also a wide range of Ex-certifications, including IECEx, ATEX, CSA.

The instrument does not require any consumables and does not require regular maintenance. The absence of extractive conditioning systems further improves availability of the measurements and eliminates errors related to sample handling.

Once power, data lines and purge are connected, the instrument is ready to use and measurements are performed in real-time.

Certifications and approvals

- IECEx/ATEX Zone 1

- IECEx/ATEX Zone 2

- CSA Class 1/Div 2 A,B,C,D

- TÜV (QAL 1 for HCL and NH3 and HF, HCL and NH3 possible in combination with H2O)

- MCERTS for HF, HCl+H2O and NH3+H2O

- EURO VI for NH3

Gases

- CH4

- CO %

- CO ppm

- CO+CO2

- CO+H2O

- CO+CH4

- CO+temp.

- CO2 %

- CO2 ppm

- H2O %

- H2S

- H2S + CO2

- HCl

- HCl+H2O

- HCl + CH4

- HCl in VCM

- HCN

- HCN + NH3

- HF

- HF + H2O

- N2O %

- N2O ppm

- NH3

- NH3+H2O

- NO

- NO2

- O2

- O2+temp

- C2H2

- C2H4

- C2H3Cl

- C2H4O

- C3H6

- CH2O

- CH3l

- COS

- C3H3N

- CH2Cl2

Features

- Response time down to 1 second

- No gas sampling: in-situ measurement

- Non contact measurement

- No interference from background gases

- Applicable for many process conditions:

– high/low temperature

– high dust

– corrosive gases - In-line measurement, integral concentration over the full stack diameter

- ATEX/IECEx and CSA certified

- TÜV, MCERTS, GOST approved technology for some gases

- Integrated span check option available

- Suitable for harsh environment

- No zero drift

- Stable calibration

- Long path lengths

Applications

- Chemical industry

- Petrochemical industry

- Metal industry

- Power plants

- Waste incinerators

- Cement industry

- Automotive industry

- Scrubber technology

- Glass industry

- PVC production

- Pulp and paper

- ..and more

Customer benefits

- In-situ monitoring

- Highly reliable real-time analyzer

- Low maintenance cost

- Reduce emission to the environment

- Easy to install and operate

- Reduce daily operation costs

- Optimize process

- Well proven measurement technique

- Tailor made to your process

Datasheets

Find distributor

Choose country

search