Technology

A journey from industry to science – and back

Innovative Technology

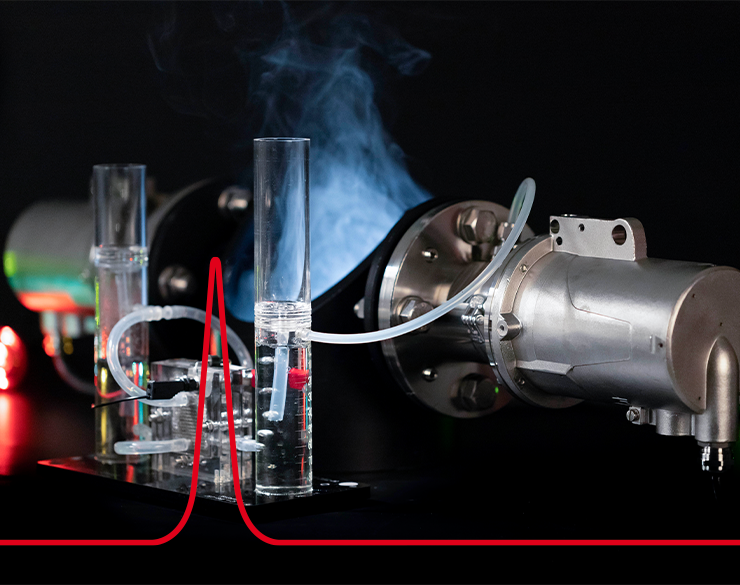

At NEO Monitors, innovation is at the core of everything we do. We harness the power of photonics – the science of light – to revolutionize industrial gas measurement. Our cutting-edge laser-based analyzers enable precise, contactless measurements, ensuring reliability even in the harshest industrial environments. By continuously pushing technological boundaries, we transform complex industrial challenges into smart, future-ready solutions.

Innovation thrives where science meets real-world applications. That’s why we actively collaborate with leading research institutes in national and international projects. By translating industrial needs into breakthrough optical technologies, we have pioneered products like our Multi Pass cell and LaserGas™ Q series – setting new standards in industrial sensing.

We are leaders in TDLAS – Tunable Diode Laser Absorption Spectroscopy for a reason – it is what we have dedicated our selves to, and we never stand still. As industries evolve, so will we.

Gas sensing with lasers

Tunable Diode Laser Absorption Spectroscopy (TDLAS) is a groundbreaking technology transforming industrial gas analysis. TDLAS utilizes the interaction between light and gas molecules. Each gas has a distinct “fingerprint” characterized by specific wavelengths of light absorbed. By tuning a laser to these wavelengths, we can detect and quantify gases with exceptional precision. Unlike traditional light sources, lasers emit light at a single wavelength, which can be fine-tuned using temperature and current adjustments. This makes TDLAS a powerful, selective, and highly sensitive gas measurement technology.

-

Critical pieces in a big puzzle

Dynea is one of the world’s leading manufacturers of industrial adhesives, primarily for the wood and paper industries, but also for rock wool and fiberglass products. We needed to upgrade our monitor equipment. We contacted NEO Monitors and the competence and knowledge we encountered made the choice easy. We’ve never had such stable and accurate measurements before,” says Christian Steen Øverland, Senior Engineer at Dynea.

-

Exceeding expectations: Safer and better

At Elkem’s plant in Salten, Norway, silicon is produced from quartz in a high-temperature process using coal and coke as reducing agents.

Elkem’s focus on the environment and safety requires full control and monitoring of all aspects of the production process. In 2009, we carried out an extensive measurement campaign at our plant. This was the beginning of our cooperation with NEO Monitors, says Nils Eivind Kamfjord. During the campaign, the NEO Monitors analyzers exceeded our expectations. We performed long time series measurements with accurate results.

-

Monitoring for the golden balance

Yara’s plants in Porsgrunn used to measure and register emissions manually, which was a time-consuming process with the risk of human error. They saw the need for automated, fast and accurate monitoring. NEO Monitors responded with an in-situ solution that provides accurate and fast monitoring directly in the stacks. By analyzing the emissions, we were able to reduce them and find the golden balance, says Karina Aas, Chief Engineer in the Technical Department at Porsgrunn.

-

NEO Monitors conquers the Quasi-impossible

China is the factory of the world, powered by its abundant coal resources. China is facing a huge environmental challenge associated with fossil fuel-fired power plants. Therefore, China has been technically retrofitting the engines of its economy by introducing emission control devices. Selective Catalytic Reduction (SCR) technology is one of the most widely used emission control solutions in China’s power industry. In this case study, you can read about Qiangui Panxian Power Plant, which faced challenges in ammonia slip measurement.

-

Cutting costs and enhancing precision with laser-based gas analysis

In mid-2012, SK Innovation conducted a demonstration installation of NEO Monitors’ oxygen analyzers. The laser technology used in NEO Monitors’ solutions was new to the Korean market. After a 6-month demo period, SK Innovation carefully evaluated the test unit based on many parameters. The result was very positive and proved that NEO Monitors’ solutions were superior to the competition.

TDLAS is better with music

Deep dive into our cutting-edge IROSS™ signal processing algorithm, which is set to revolutionize the future of TDLAS. This game-changing technology expands possibilities and reduces interference through a source separation algorithm inspired by the music industry. It enables multi-component measurements in real time and allows to combine purposes such as process control and safety, opening up a world of possibilities. Enjoy reading!

Find your solution

If its gas, and it needs control, you want NEO Monitors. Discover our solutions – direct measurement for direct control.

Find your solution