Deposits of coke inside industrial furnace tubes degrade heat transfer efficiency, increase pressure drop, and necessitate costly shutdowns for decoking. Coke buildup is a common issue across various industries, particularly petrochemical and refining operations, where hydrocarbon streams undergo high-temperature processing. This buildup negatively impacts overall operational efficiency, leading to increased energy consumption, reduced throughput, and potential safety hazards. Real-time monitoring using Tunable Diode Laser Absorption Spectroscopy (TDLAS) enables operators to optimize the decoke process by continuously measuring critical gas species, primarily carbon dioxide (CO2). While monitoring carbon monoxide (CO) can provide additional insights, particularly in detecting incomplete combustion, focusing on CO2 alone typically provides sufficient information for effective decoking. Implementing TDLAS technology allows operators to gain actionable insights, achieve precise control over maintenance cycles, enhance plant safety, and significantly reduce operational costs by minimizing unnecessary downtime and resource consumption.

Application: Furnace Decoking

Furnace decoking is a critical maintenance process involving the controlled combustion or oxidation of accumulated coke deposits within furnace tubes. Coke formation occurs due to thermal cracking of hydrocarbon feedstock under high-temperature conditions, leading to decreased operational performance.

During decoking, steam and air is introduced to burn off these coke deposits. As the coke combusts, it generates measurable concentrations of CO₂ gas, and potentially CO if combustion is incomplete. In-situ monitoring of CO₂ levels with TDLAS provides critical information on the progress and efficiency of the decoking process, enabling precise control of cleaning cycles. Accurate real-time monitoring ensures the process continues only until the coke deposits are thoroughly removed, minimizing downtime and energy usage while extending the operational life of the furnace. Utilizing TDLAS in-situ significantly reduces maintenance needs and increases process uptime by eliminating the complications and delays associated with traditional sampling methods.

Real-time tracking helps identify:

• Onset of Decoking: Initial increase in CO2 indicating the start of coke combustion.

• Decoking Rate: Rate of increase and peak levels of CO2 to gauge efficiency.

• Endpoint Determination: Accurate detection of the endpoint through the return of CO2 concentrations to baseline levels.

This comprehensive monitoring approach enhances both the safety and efficiency of furnace operations.

Process temperature: Typically, 300 – 400 °C *

Process pressure: 975 – 1,015 mbarA *

CO2 concentration: Mid-cycle 9% (Typical range 0 – 25%)

CO concentration (optional): Mid-cycle 1% (Typical range 0 – 10%)

(*) Temperature and Pressure transducer is highly recommended.

NEO Monitors’ solution

NEO Monitors’ LaserGas™ III Ultra analyzers are the benchmark for industrial TDLAS technology. With best-in-class detection limits and an unmatched dynamic range of seven decades, they are the ideal choice for decoking and many other applications. LaserGas™ III CO2 Ultra is recommended for this application. Optionally, it can be used in combination with LaserGas™ III CO Ultra if it is also required to measure CO.

All LaserGas™ products offer:

- Sensitive and selective

- Contactless

- Fast response time

- No drift of zero/span

- Low maintenance requirements

- High reliability and longevity

LaserGas™ III Ultra analyzers use NEO Monitors’ proprietary IROSS™ signal processing algorithm, which eliminates certain cross-sensitivities to other gas components that may be present in the process.

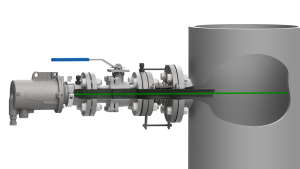

Installation recommendation

For optimal performance and reliability, it is recommended to install the LaserGas™ III CO2 Ultra analyzer downstream of the furnace tubes, but upstream of separators or scrubbers. Ideally, position the analyzer close to the furnace outlet to ensure accurate gas measurement and prevent interference from condensation or gas-liquid interactions.

For further information, see IROSS™ – NEO Monitors’ proprietary signal processing

Application Note: Monitoring Furnace Decoking with TDLAS