We are pleased to share our latest research article, “Sensing of molecular Hydrogen using direct Tunable Diode Laser Absorption Spectroscopy ” published in Optics Express.

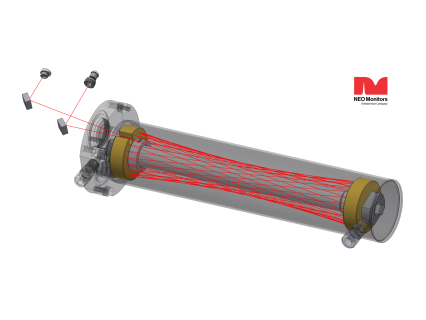

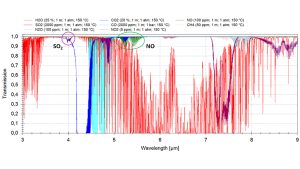

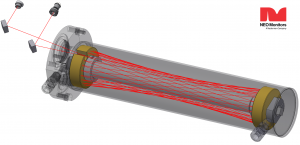

In this study, we present precise laboratory measurements of molecular hydrogen with TDLAS, showing high sensitivity and excellent linearity over a wide concentration range. By using a multipass cell with an optical path length of 11.4 meters, we achieved a minimum detectable concentration of 1.2 ppmv at an averaging time of 100 seconds, highlighting the capabilities of this approach.